Solar PV Critical Fastened Joints

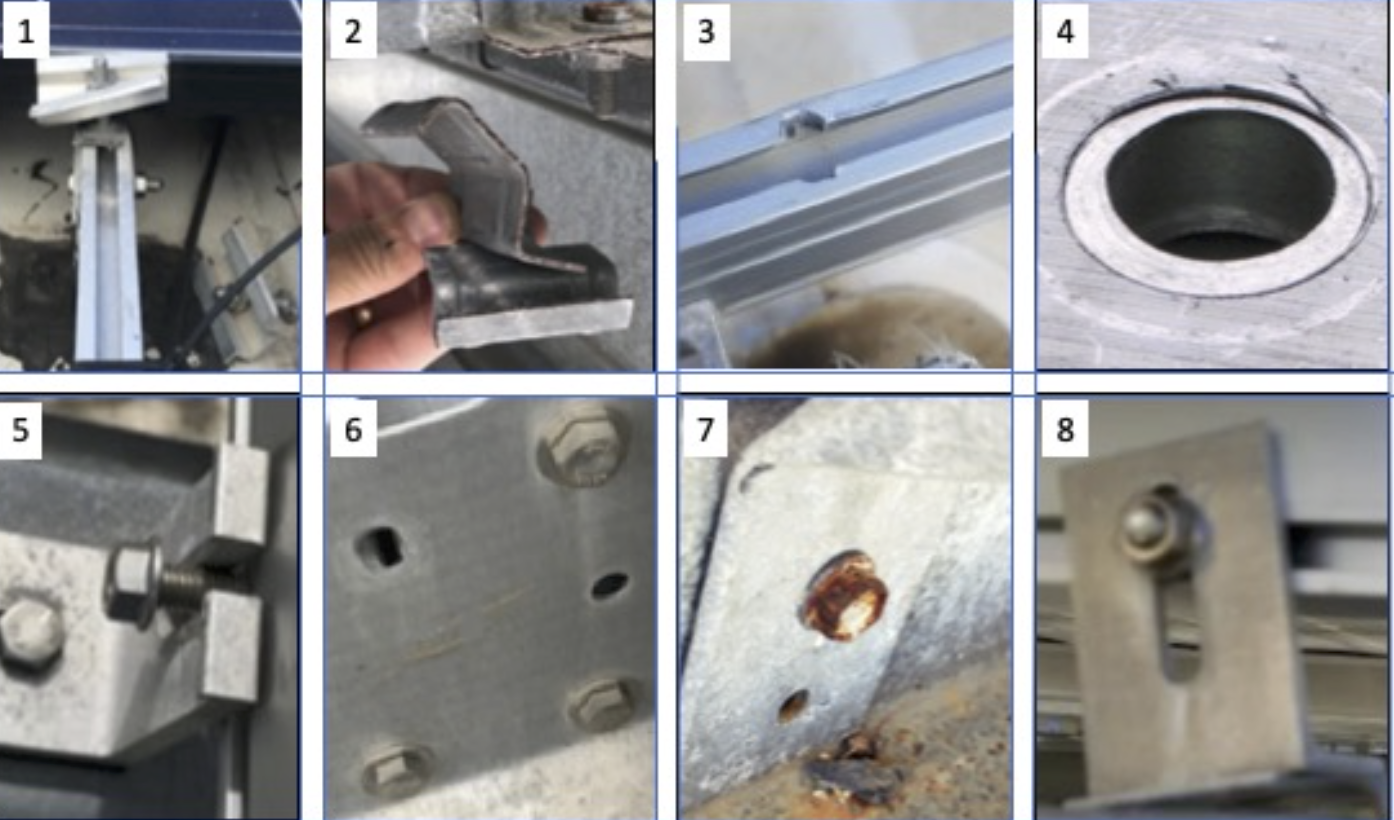

Critical fastened joints are a source of significant wind-related failures for solar PV systems, but the nature of critical fastened joint failures is not well understood. This research effort aims to assist in diagnosing failure modes and maturing critical fastened joint designs, through the point of installation and management, as is seen in other industries.

What are Critical Fastened Joints?

Fastened joints are an assembly of components (fasteners, clips, washers, brackets) used in installing a PV system, including module attachment, racking, tracker interconnections, and attachment to underlying structures not covered by AISC 360.

brackets) used in installing a PV system, including module attachment, racking, tracker interconnections, and attachment to underlying structures not covered by AISC 360.

Project Background

Common types of fasteners used in solar PV systems are not well represented in code. Current engineering practices assume static loading on PV structures when actual conditions are highly dynamic. This results in otherwise code-compliant solar structures failing at wind speeds below design levels. Field inspections of these systems have revealed that bolted joint issues are often at the root of system failure.

Research Goals

The main goal of this research is to advance bolted joint technologies and practices used in mounting modules and assembling racking systems. The team seeks to support bringing bolted joint practices in the solar PV industry to the same level of maturity as seen in other industries such as transportation and buildings. These industries have followed well developed codes and standards to attain a state of high volume, low cost and high reliability, which are hallmarks of maturity.

To help advance bolted joint technologies, the team is:

-

Interviewing industry stakeholders to characterize the failures commonly seen in PV systems’

-

Developing guidance documents targeted to design engineers, developers, authorities having jurisdiction (AHJs) and financial services companies;

-

Identifying transferable knowledge from buildings, transportation and aerospace industries;

-

Identifying key codes and standards gaps that can become focal points for the guidance documents;

-

Characterizing the dynamic loading on, and capacities of, critical fastened joints through modeling and lab testing;.Understand the full life-cycle cost implications of hardware choices using levelized cost of electricity (LCOE) as the main metric.

Get Involved!

We want to engage with stakeholders, including system owners and operators, consulting engineers, product manufacturers, contractors and system commissioning agents. If you have experience with the types of fastened joints commonly found in solar PV systems and would be interested in participating in an interview, please fill in our short outreach survey found here.

All results will be held in strict confidence, and the final report will not include references to any manufacturers, companies, locations or individuals.

We also are interested in collaborating on best practices in computational fluid dynamics and finite element analysis modeling of solar structures and critical fastened joints under dynamic loading conditions. We are also interested in collaboration with experts in life-cycle cost models and other tools used by the financial and insurance industries. Topics will include the integration of risk into these models. If you are interested, please contact the research team at PV_Fasteners@lbl.gov.

For any questions regarding the interview process or collaboration please contact: PV_Fasteners@lbl.gov

Tools and Training

In this training, James Ellsworth from the National Renewable Energy Laboratory gives an overview of the critical fastened joints research effort's objectives and research tasks

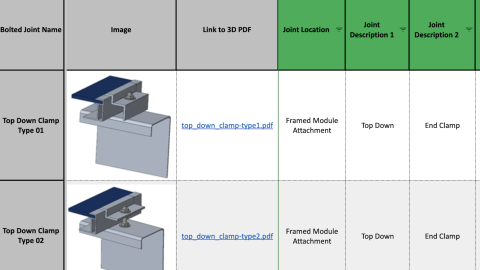

In this video, John Ness of Matrix Engineering Consultants and Frank Oudheusden and Chris Needham from FCX Solar explain a recently developed framework which classifies known solar PV joint types, the related failure mechanism causes and failure effects

The fastened joint classification system is intended to also provide industry stakeholders with a common language by which to describe fastened joints used in solar PV racking and module mounting systems.

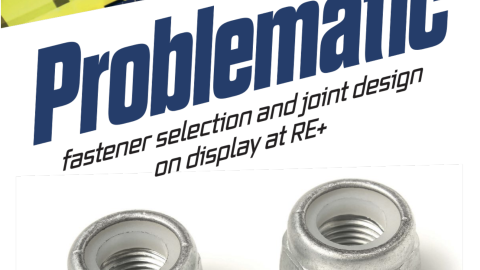

In the News

Check out this recent article published in Solar Builder magazine.

Meet the Critical Fastened Joints Research Team

Dr. Marie K. Mapes, Ph.D. DOE/SETO: Photovoltaic technology manager for the U.S. DOE’s Solar Energy Technologies Office (SETO). Her work focuses on creating photovoltaic research and development programs that will advance the use of photovoltaic energy, and leading evaluation and assessment activities to improve the effectiveness of these programs.

Dr. Alan Ward, Ph.D. DOE/SETO: Photovoltaic scientist and technology manager for the Solar Energy Technologies Office, working as a member of the photovoltaics team since May 2020. He support PV development projects focused on innovations in materials and designs for low cost and high reliability, at both the module and system levels of integration.

Gerald Robinson, Lawrence Berkeley National Laboratory: Project PI. Experience leading research teams. Led Caribbean investigations for US-GSA of four failed arrays and developed recovery plans for federal agencies experiencing storm-related losses. Technical lead for FEMP Solar PV Technical Specifications project.

James Elsworth, National Renewable Energy Laboratory: Project co-PI. Actively engaged in multiple PV severe weather and system resilience topics. Published paper on cost impacts of weather hardening and will lead the cost accounting efforts to understand LCOE impacts.

Jon Ness, Matrix Engineering: Engineer and subject-matter expert with experience in the design, validation and installation of dynamically loaded bolted joints including those used in solar PV systems. Consultant to PV system owners, examining root cause failures and engineering bolted joint retrofits.

Dr. Tracy Becker, University of California Berkeley: Assistant Professor, Department of Civil and Environmental Engineering. Conducts research on a wide range of structural engineering topics and is supported by two major laboratory facilities capable of full-scale, dynamic testing.

Chris Needham, FCX Solar: Aerolastic engineering, product and retrofit designs. Background as engineer with racking product designs and consulting for system owners.

Frank Oudheusden, FCX Solar: Engineer and subject-matter expert on solar PV structures and bolted joints. Firm specializes in PV system engineering, racking design and consulting for system owners.

Joe Cain, Solar Energy Industries Association: Engaged with racking manufacturers, codes and standards and has co-authored two seminal SEAOC guidance documents.

George Kelly, American Renewable Energy Standards and Certification Association: Expert on module reliability, certifications and qualification testing, with leadership roles in the development of international standards through IEC and ASTM. Founding member of the American Renewable Energy Standards and Certifications Association (ARESCA), formed in 2015 to foster renewable energy standards and certification efforts.

Dr. Xinlong Du, UC Berkeley: Postdoctoral scholar at UC Berkeley. He is looking at the failure of solar arrays in wind storms. Specifically, he is working on fatigue failure of bolted joints of solar photovoltaic (PV) structures through finite element analysis, computational fluid dynamics, and wind hazard analysis for life-cycle studies.